Processes

TWI specializes in highly flexible and efficient processes. Our facilities are designed to be competitive on high, medium, and low volume programs. Through our process engineering development center, continuous improvement policies, and our quality teams we ensure our resources are being used efficiently, and our products are meeting our high performance standards.

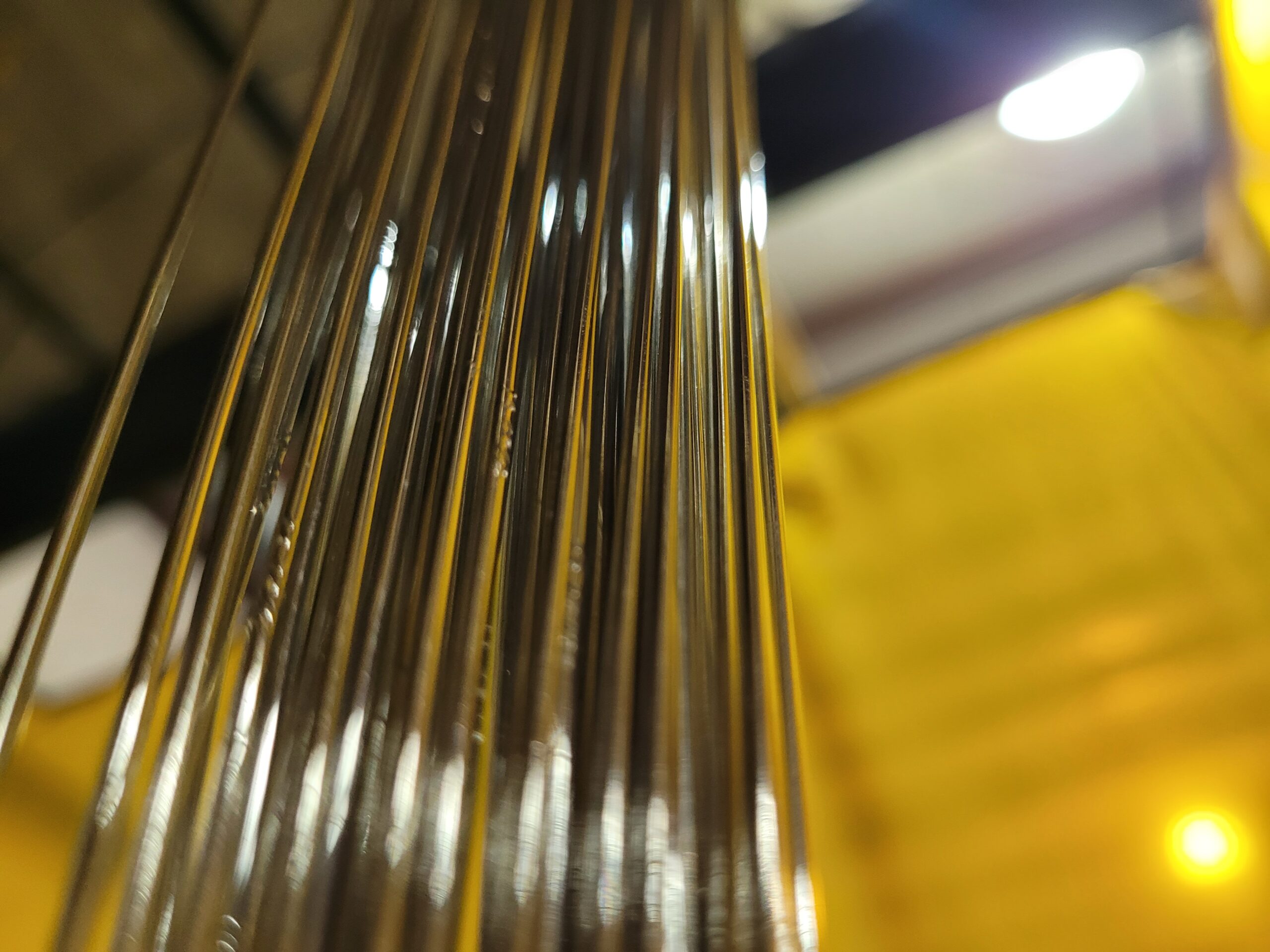

We boast a design and development center where we plan new programs, quickly build prototypes, and develop all tooling needed for new parts. We put our products to the test with our new thermal cycle testing facility, other leak testing, and many more checks to ensure the safety of our products. We have many manual and automated tube benders, end-formers, saws, deburring machines, a plasma laser, and much more. Additionally, we house 5 tube mills, 4 injection molding machines, an entire brazing plant, and 35 stamping presses.

Our diverse number of in-house processes allows us to accommodate a variety of customer needs while keeping costs low.

Click on any of the processes below to learn more!